How to Spot Overhead Crane Wear and Tear Early& Reduce Hazards

Learn how crane buyers and operators can detect early signs of wear and tear. Prevent downtime, reduce repair costs, and keep your overhead cranes safe and reliable with practical inspection tips and maintenance strategies.

Introduction: Why You Can’t Ignore Crane Wear and Tear

Overhead cranes are the backbone of many workshops, factories, and steel plants. Yet, too often, buyers and operators focus only on lifting capacity, span, or upfront cost. What gets overlooked? Maintenance, reliability, and hidden downtime risks.

Real-Life Warnings

You don’t need to wait for a disaster to learn the hard way. Operators share stories like:

- “We skipped inspections for months, and a wire rope frayed unexpectedly.”

- “A near miss last week could have been prevented with routine checks.”

- “Repair bills came out of nowhere and hit our budget hard.”

These examples show that even a well-built crane can become a liability without proper care.

The purpose of this guide is to give buyers and operators a practical approach to spotting wear and tear early. If you know what signs to look for, you can:

- Schedule timely inspections before small issues become big problems.

- Reduce downtime and avoid unexpected repair costs.

- Keep your facility safer for operators and staff.

In short, noticing wear and tear early is not just about safety—it’s about protecting your investment and running your operations smoothly.

From Downtime to Danger: What Happens If You Ignore Crane Maintenance

Neglecting crane maintenance isn’t just an operational headache—it can quickly turn into a financial and safety disaster. Many buyers and operators underestimate how quickly small issues add up. A worn wire rope, a slipping brake, or a corroded hook might seem minor, but ignoring these signs can lead to serious consequences.

The Hidden Costs of Poor Maintenance

When maintenance is skipped or delayed, costs appear in several ways:

- Repairs and replacements: Fixing a snapped wire rope or a failed motor is far more expensive than routine preventive maintenance.

- Downtime: Every hour your crane is out of service slows production and can disrupt entire workflows.

- Operational delays: Projects may miss deadlines because material handling is interrupted.

- Indirect costs: Emergency repairs, overtime labor, and potential damage to other equipment.

Safety Risks You Can’t Afford to Ignore

Failing to maintain your crane isn’t just about money—it’s about people. Neglected components increase the risk of:

- Accidents and injuries: From minor bruises to life-threatening incidents.

- Liability and compliance issues: Workplace safety violations can lead to fines or insurance penalties.

- Near misses: Even small warnings ignored today can lead to serious incidents tomorrow.

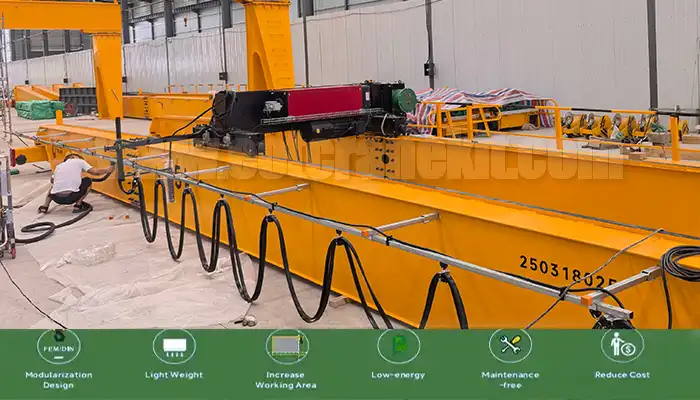

How Smart Buyers Protect Themselves

Investing in a crane with well-designed parts, durable components, and accessible maintenance pays off over time. Buyers should look for:

- High-quality wire ropes, hooks, and motors that last longer under heavy use.

- Certifications or third-party inspections to ensure reliability.

- Clear service and maintenance guidelines from the supplier.

How to Detect Wear and Tear in Your Crane Before It's Too Late

Even the best-built overhead cranes won't last forever. Parts wear out, components loosen, and over time, small problems can escalate into serious safety hazards. For crane buyers and operators, knowing the early signs of wear and tear is essential. Catching issues early helps prevent downtime, expensive repairs, and, most importantly, accidents.

1. Wire Ropes and Chains

These are the lifelines of your crane. Watch for:

- Fraying or broken strands

- Corrosion or rust buildup

- Unusual stretching or elongation

Regular visual inspection can catch most of these issues before they become critical.

2. Hooks

The hook bears the weight of every lift. Signs it needs attention include:

- Cracks or bends in the hook body

- Deformation or change in the throat opening

- Excessive wear on the hook tip or latch

Even a small deformation can reduce load capacity and increase accident risk.

3. Gears and Bearings

These components ensure smooth operation. Problems to look for:

- Grinding or unusual noises during operation

- Overheating or discoloration from friction

- Misalignment or vibration

Some of these require a more technical inspection or professional assessment.

4. Brakes and Clutches

Critical for controlling load movement safely:

- Slippage under load

- Longer stopping distances than usual

- Irregular sounds or vibrations

Timely adjustment or replacement can prevent costly accidents.

5. Electrical Components

Electrical failures can be sudden and dangerous:

- Sparks or short circuits

- Overheating of motors or cables

- Loose or corroded connections

Regular visual and functional checks are necessary for safety.

6. Steel Structure

The crane's frame and girder need constant attention:

- Fatigue cracks or hairline fractures

- Corrosion, especially in outdoor or humid environments

- Weld failures or loose bolts

Structural damage often requires professional inspection but early visual signs should never be ignored.

7. Practical Inspection Notes

- Visual checks: Wire ropes, hooks, paint deterioration, corrosion, and minor cracks can often be spotted without tools.

- Technical inspection: Bearings, gears, electrical systems, brakes, and structural integrity often require a qualified technician or measurement tools.

- Schedule regular inspections based on crane usage and manufacturer recommendations.

Practical Crane Maintenance Tips Every Buyer Should Demand

Maintenance isn't just a task for your workshop team—it's a critical part of protecting your investment. Overhead cranes are heavy-duty machines, and even minor issues left unchecked can cause downtime, costly repairs, or accidents. For buyers, understanding preventive maintenance helps you ensure your cranes remain reliable and safe from day one.

1. Daily Checks for Operators

Operators are the first line of defense against crane problems. Simple daily checks can catch issues before they escalate:

- Inspect wire ropes and chains for fraying, kinks, or corrosion.

- Check hooks and latches for deformation or wear.

- Listen for unusual noises during lifting or moving operations.

- Ensure controls, buttons, and emergency stops are functioning properly.

- Look for oil leaks, loose bolts, or visible structural issues.

2. Weekly and Monthly Inspections for Maintenance Teams

Maintenance teams should perform more detailed inspections on a regular schedule:

- Lubricate gears, bearings, and wire ropes as per manufacturer guidelines.

- Check brakes, clutches, and motor alignment.

- Inspect electrical systems for loose connections, wear, or overheating.

- Examine steel structures, welds, and fasteners for cracks or fatigue.

- Test load-bearing and safety devices to ensure proper function.

3. Scheduled Major Inspections

Some inspections are larger in scope and only need to be performed annually or every two years, depending on usage and environment:

- Comprehensive structural integrity assessment of girders and frames.

- Detailed electrical and mechanical system testing.

- Professional load testing and certification to meet safety regulations.

- Full service of hoists, brakes, and control systems.

4. Buyer Perspective: What to Ask From Suppliers

When purchasing a crane, buyers should not only focus on the price or lifting capacity—they should also ensure proper maintenance support:

- Request maintenance manuals and detailed inspection checklists.

- Ask if the supplier provides training for operators and maintenance staff.

- Confirm availability of spare parts and technical support for long-term reliability.

- Check whether the crane comes with recommended maintenance schedules tailored to your usage.

How to Choose Reliable Overhead Cranes That Reduce Wear and Tear

Not all cranes are created equal. Two cranes might have the same lifting capacity, but one could require frequent repairs while the other runs smoothly for years. For buyers, understanding reliability is essential to minimize downtime, maintenance costs, and safety risks.

1. Ask About Expected Service Life of Key Parts

Durable components make a huge difference in long-term performance. When evaluating a crane, ask the supplier about:

- Wire ropes and chains: how many hours of service life are expected under typical loads.

- Motors and drives: whether they are industrial-grade and how often they require servicing.

- Brakes and clutches: expected operational cycles before replacement is recommended.

Knowing these details helps plan maintenance schedules and anticipate part replacements.

2. Consider Supplier Reputation and Certifications

A crane's reliability often reflects the manufacturer's quality standards. Buyers should check:

- CE or ISO certifications for compliance with international quality and safety standards.

- Whether the supplier provides third-party inspections for added assurance.

- Past client reviews and references to confirm long-term performance in similar applications.

3. After-Sales Service and Spare Parts Availability

Even the most reliable crane needs maintenance. Before purchasing, ensure:

- Spare parts are readily available locally or through the supplier.

- Technical support is accessible for troubleshooting or emergency repairs.

- The supplier offers training and guidance on routine maintenance.

4. Lifecycle Cost Comparison

It's tempting to choose a low-cost crane upfront, but cheap cranes can be expensive over time. Consider:

- Frequent downtime and emergency repairs versus fewer scheduled services.

- Replacement costs for worn-out parts compared to industrial-grade components.

- Operational efficiency: a reliable crane minimizes interruptions and keeps production on schedule.

Choosing a crane isn't just about lifting capacity—it's about picking a solution that stays dependable, safe, and cost-effective for years.

Dynamic Lifting Hook Tracking System for Overhead &Gantry Cranes

Smart Monitoring: How Modern Cranes Prevent Wear and Tear

Technology is changing the way overhead cranes are maintained and operated. Modern solutions like sensors, IoT monitoring, and predictive maintenance systems give buyers and operators an early warning before small problems turn into major failures. These systems help extend the life of parts, reduce downtime, and improve overall safety.

1. Benefits of Sensors and Predictive Maintenance

- Continuous monitoring: Sensors track critical parameters such as load weight, motor temperature, vibration, and brake performance.

- Early alerts: Systems notify operators of abnormal wear, loose connections, or unusual vibrations before they cause breakdowns.

- Data-driven maintenance: Maintenance schedules are optimized based on actual crane usage, rather than relying solely on calendar-based inspections.

- Reduced downtime: Fewer emergency repairs mean less interruption to operations and lower repair costs.

2. How Automation Helps Protect Crane Components

- Consistent operation: Automated load handling reduces sudden jerks or improper movements that accelerate wear.

- Operator support: Features like anti-sway, speed control, and collision avoidance reduce human error, extending the life of ropes, hooks, and brakes.

- Safety improvements: Intelligent systems reduce the risk of accidents caused by overloading or misuse.

3. Buyer Tip: Evaluating Intelligent Features

Before investing in advanced technology, consider:

- Facility needs: Does your operation handle heavy, irregular, or delicate loads that benefit from precise monitoring?

- Cost vs. benefit: Weigh the upfront investment against potential savings in downtime, repairs, and safety compliance.

- Supplier support: Ensure the supplier offers training, installation, and ongoing technical assistance for monitoring systems.

Modern technology is no longer optional for buyers who prioritize reliability and safety. Even a small investment in smart monitoring can prevent major failures, extend component life, and keep your operation running smoothly.

Tools You Can Use: Checklists, Inspections, and Maintenance Planning

When it comes to crane maintenance, having the right tools and resources makes a huge difference. Buyers and operators who plan ahead can prevent costly repairs, reduce downtime, and keep their teams safe. Practical resources like checklists, logs, and charts simplify inspection routines and help track maintenance over time.

1. Inspection Checklists

- Daily, weekly, and monthly inspection checklists ensure nothing is overlooked.

- Visual inspections for hooks, wire ropes, brakes, and steel structures can be recorded quickly.

- Functional checks for motors, controls, and electrical components help catch issues early.

- Tip: Many suppliers provide free downloadable checklists—request these when buying a new crane.

2. Lifecycle Cost Comparison

- Comparing cranes isn't just about the purchase price.

- Include expected maintenance, part replacement, and downtime costs in your calculation.

- Example: a slightly higher upfront cost for a crane with durable components often results in lower costs over 5–10 years.

- Tip: Create a simple chart to visualize cost differences between models.

3. Maintenance Log Template

- Keep a log for every inspection and repair performed on your cranes.

- Record dates, observations, actions taken, and parts replaced.

- Logs help with warranty claims, regulatory compliance, and future resale value.

- Tip: Encourage operators and maintenance teams to update logs consistently—small notes can prevent big problems later.

4. Buyer Tip: Negotiating Support

- Ask suppliers to provide training for operators and maintenance teams.

- Include ongoing maintenance support or service agreements in the purchase.

- Confirm access to spare parts and technical guidance for long-term reliability.

- These resources make daily operations smoother and protect your investment over time.

By equipping your team with practical tools and structured maintenance routines, you can catch wear and tear early, plan repairs efficiently, and ensure your cranes stay safe and reliable for years.

Conclusion: Safer Cranes, Lower Costs, Stronger Investments

Keeping an overhead crane safe and reliable isn’t just about avoiding accidents. It’s about saving money, protecting your team, and making sure your operation runs without unexpected stops.

Spot Problems Early

- Look for wear and tear before it becomes a hazard.

- Catch small issues with wire ropes, brakes, and hooks early.

- Early detection keeps downtime and repair costs to a minimum.

Plan for Reliability

- Factor in maintenance needs and component durability when choosing a crane.

- Cranes with robust parts and clear inspection guidelines often cost less over time.

- Keep logs and follow inspection routines—it really pays off.

What Buyers Should Do Now

- Ask suppliers about the expected life of parts like motors and wire ropes.

- Get inspection schedules and maintenance manuals up front.

- Confirm availability of spare parts and after-sales support.

A little planning upfront goes a long way. By focusing on maintenance and reliability, you’re not just buying a crane—you’re securing safety, efficiency, and long-term savings for your operation.